We all have that one picture sitting in our phone gallery or computer folder that screams “this deserves more than a like”. Maybe it’s your football club’s mascot, your company logo, or even a goofy doodle from your mate that somehow became an inside joke.

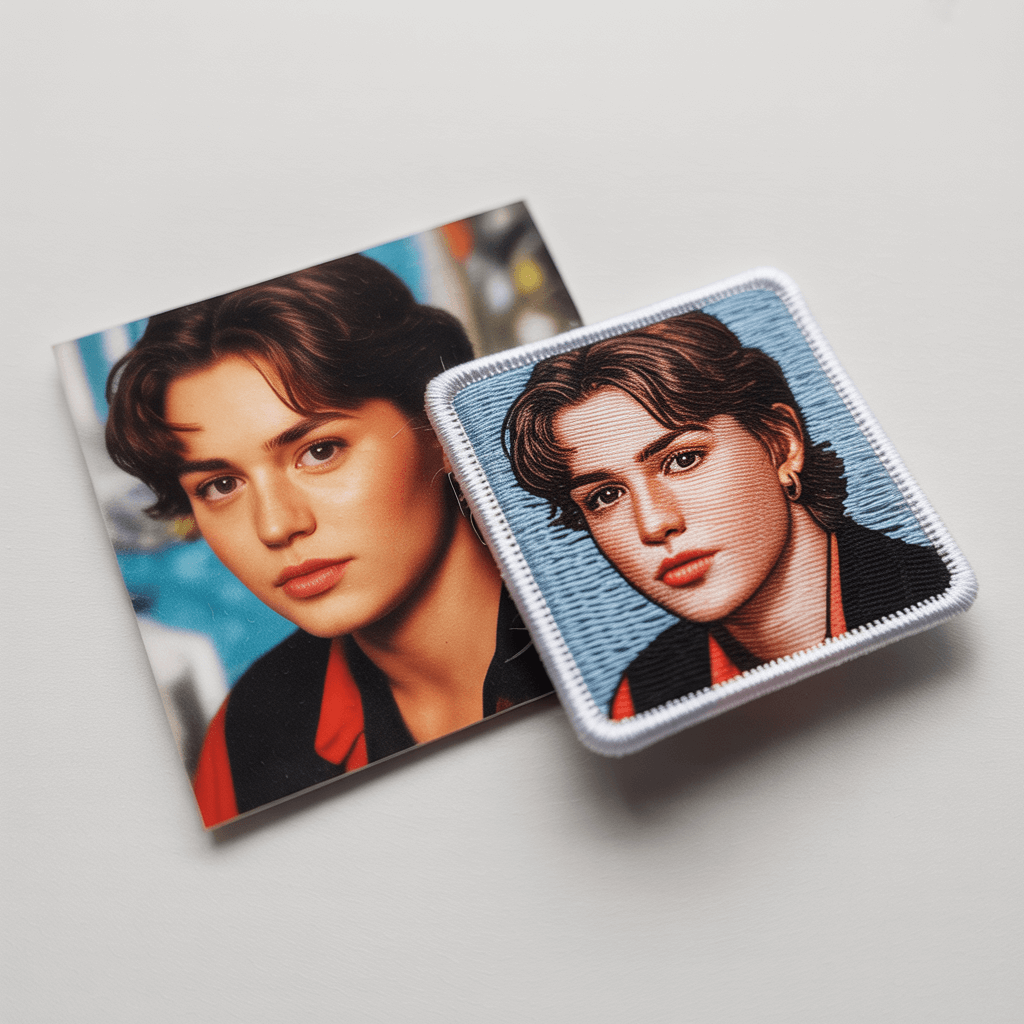

Whatever it is, turning that image into a custom embroidered patch is like giving it a glow-up: now it’s wearable, collectible, and, let’s be real, way cooler than just slapping it on Instagram.

Transforming a flat digital image into a high-quality embroidered patch made in the UK isn’t just a copy-paste job. It’s art, science, and craftsmanship stitched together. If you’re wondering how that transformation actually happens (and why choosing the best patch maker in the UK matters), buckle up, we’re about to spill the threads.

Step One: Choosing the Right Image

Not every picture makes a great patch. The secret? Simplicity sells.

Photos overloaded with details or gradients can lose their magic once translated into thread. But bold logos, mascots, initials, or stylised designs? Chef’s kiss, they’re perfect. Think of it this way: you want clean lines and strong contrast, not a 4K landscape photo crammed into a two-inch circle.

This is where a custom patch maker near me (or rather, a pro like Patch Makers UK) comes in clutch. They’ll help you refine your design so it looks just as sharp stitched on a hoodie as it does on your phone screen.

Step Two: Digitising (The Secret Sauce)

Here’s a fun fact: embroidery machines can’t read JPEGs or PNGs. Your design has to be digitised, aka converted into a stitch file that tells the machine where to poke, pull, and loop thread.

Digitizing is an art form. A skilled technician decides:

- Where the stitches start and end

- Which stitch types (satin, fill, run) to use

- How to balance density so your patch isn’t stiff as cardboard

This is the step that separates cheap custom patches with no minimum from patches that look like they came straight off a pro football kit.

Step Three: Selecting the Patch Style

That picture you’re turning into a patch? It could live many lives.

- Custom Embroidered Patches – Classic, textured, timeless. Perfect for logos, mascots, or team crests.

- Custom Woven Patches – More detail, thinner threads, ideal for intricate linework.

- Custom PVC Patches – Bold, durable, waterproof—hello sports gear and outdoor wear.

- Custom Chenille Patches – That varsity jacket, fuzzy-letter vibe.

- Custom Printed Patches – Best for photorealistic designs when embroidery can’t capture it.

Already overwhelmed? Don’t be. With a UK #1 custom patch manufacturer like Patch Makers UK, you can literally design your own patch and order in just a few clicks.

Step Four: Patch Backings (Iron, Sew, Stick or Velcro?)

Your picture might become a patch, but how’s it sticking to your stuff? Backings change everything:

- Iron-On – Quick and easy. Heat press and done. Great for DIYers.

- Sew-On – Old-school durable. Perfect for uniforms, biker jackets, and heavy fabrics.

- Velcro Backed – Tactical, removable, swap-friendly. Favoured in custom military patches UK.

- Adhesive Stick-On – Temporary fixes or events.

- No Backing – For pro stitchers who want to embed the patch into fabric.

Pro tip: If you’re attaching to tricky fabrics like velvet, check out our guide on How To Make & Attach Custom Embroidered Patches To Velvet.

Step Five: Size, Shape & Borders

Want your patch to scream “look at me” or whisper subtle branding? That’s all in the sizing. Big patches work for custom logo patches for jackets, small ones are killer for hats, bags, or subtle flexes.

Borders also play a role:

- Merrowed Edge – Clean, classic, perfect for circles and rectangles.

- Heat Cut Edge – Precise, sharp, works with funky shapes.

Step Six: Sampling & Production

Before your picture graduates into a full batch, pros always send a sample patch. That’s your moment to check colours, threads, and overall vibe. Once approved, the machines roll out your order, whether it’s a single personalised embroidery patch or bulk custom patches for uniforms.

And yes, with a fast turnaround custom patches UK option, you won’t be biting your nails waiting for weeks.

Choosing the Right Fabric for Your Picture-to-Patch Project

Not every fabric loves embroidery equally. Some materials hold stitches like champs, while others wrinkle, warp, or fray.

- Cotton & Twill – Perfect for everyday patches. Durable and crisp.

- Denim – Iconic pairing; makes embroidered patches pop.

- Felt – Soft texture, but best for decorative patches.

- Leather & PVC – Works better with applique or woven styles than heavy embroidery.

When turning your picture into a patch, the base fabric matters just as much as the artwork. If your picture has tons of fine detail, choose twill or felt for precision.

Thread Colours and Embroidery Tricks You Didn’t Know About

Ever wondered why some embroidered patches look “flat” while others look 3D and alive? It’s not just the picture, it’s the embroidery technique.

- Satin Stitch – Clean outlines, perfect for logos or text.

- Fill Stitch – Great for shading larger areas.

- 3D Puff Embroidery – Adds texture and depth (think sports logos).

- Metallic Threads – Perfect for making golds and silvers shine.

When digitizing your picture, choosing the right patch style stitch technique can totally change the final vibe of the patch.

Eco-Friendly Picture Transformations

Sustainability is a growing customer demand. More clubs and brands want eco-friendly patches that reduce textile waste.

Options include:

- Organic Cotton Twill for eco bases.

- Recycled Polyester Threads for embroidery.

- Low-Waste Digitizing to reduce thread waste.

So yes, you can turn your favorite picture into a patch and flex your eco-conscious values at the same time.

Unique Uses for Picture-Based Patches

Sure, jackets and hoodies are classics, but your embroidered patch can live way beyond clothing.

- Custom patches for hats and beanies – Fan favorite.

- Laptop bags and tech sleeves – Trendy among students.

- Club banners & flags – Adds identity to football or scout clubs.

- Event giveaways – Patches as collectibles are hot right now.

Your picture-turned-patch doesn’t have to stay stitched on a jacket, it can brand almost anything fabric.

Why DIY Doesn’t Cut It

Let’s be honest. You could Google “how to turn a photo into a patch at home” and end up with a craft disaster involving glue guns and regret. Or, you could let the best patch makers in the UK handle it with pro digitizing, high-grade threads, and quality checks.

Because the truth is, if you want your patch to last through football tackles, motorcycle rides, or washing machines, it’s worth trusting a custom patch factory that knows its stuff.

How Much Do Custom Embroidered Patches Cost?

Here’s the golden question every club, small business, or hypebeast brand owner asks: “How much do custom patches cost?”

The truth? It depends on:

- Size & Detail – Bigger, more detailed patches = more thread = higher cost.

- Quantity – Ordering 10 patches costs more per piece than ordering 500. Bulk is where the savings live.

- Backing Choice – Velcro or adhesive adds a little extra compared to sew-on or iron-on.

- Special Threads – Metallic or glow-in-the-dark? Yeah, they’ll bump the price (but also the wow factor).

That said, with Patch Makers UK, you’ll always get custom patches at low prices without sacrificing quality. Whether you’re ordering cheap custom patches with no minimum or going for bulk custom patches for uniforms, there’s flexibility for every budget.

How to Care for Your Embroidered Patches

Okay, so you’ve turned your favorite picture into a stunning patch. But how do you make sure it doesn’t fade, fray, or fall off after two washes?

Here’s the cheat sheet:

- Wash Inside Out – Protects embroidery threads from abrasion.

- Air Dry When Possible – Heat shortens patch life.

- Avoid Harsh Bleach/Detergents – They’re the enemy of bright threads.

- Iron with a Cloth Barrier – If it’s sewn-on, this keeps it smooth.

We break it all down in detail here: How to Care for and Maintain Your Embroidered Patches?. A must-read if you want your patches to look as fresh in a year as they did on day one.

FAQs

Q1: Can I really turn any picture into an embroidered patch?

Yes! Almost any picture, logo, or artwork can be converted into a patch. However, simpler and high-contrast designs translate better into clean, durable embroidery.

Q2: What file format should I use when sending a picture for patch making?

Vector files like AI, EPS, or SVG are best for digitizing. If you only have a JPEG or PNG, a professional custom patch maker can convert it before embroidery.

Q3: How much does it cost to turn a picture into an embroidered patch?

Prices vary depending on size, stitch count, colours, and quantity. Ordering in bulk lowers the cost per patch, making it affordable for clubs, businesses, and events.

Q4: What’s the best size for picture-to-patch designs?

It depends on the application. Small patches (2–3 inches) are great for hats, while larger patches (4–6 inches) are better for jackets and uniforms.

Q5: Can detailed photos be embroidered as patches?

Yes, but with limitations. Highly detailed photos may need simplification or a woven patch option to capture finer details.

Q6: Where can I order picture-to-patch embroidery in the UK?

Patch Makers UK is one of the best patch makers in the UK, offering custom embroidered patches with free design help, quick turnaround, and no minimum order.

From Picture to Patch

So, let’s recap. Taking your favorite image and turning it into a custom embroidered patch isn’t just possible, it’s a straight-up power move. From sports clubs and businesses to fashion brands and personal projects, patches are a ridiculously versatile way to tell your story, boost your brand, and stand out.

Whether you want one patch for your hoodie or bulk patches for your football club, we’ve got you covered with pro digitizing, premium stitching, and UK-based quality.

Ready to turn that picture on your phone into a patch on your chest? Contact Patch Makers UK today and let’s make it happen.